In the world of manufacturing, quality control is crucial. Manufacturers must ensure everything is correct when developing new products or starting manufacturing for a new design. That’s where the First Article Inspection (FAI) steps in. This process verifies that the initial piece fits the design specs and is ready for mass manufacturing. Learn the First Article Inspection Services (FAI), which is essential, and how to prepare.

What is FAI Material Testing?

First Article Inspection (FAI) is a thorough inspection of the first item of a production run. It’s like giving the first product an in-depth fitness test. This testing entails comparing the product against the unique layout, including drawings, specifications, and requirements. Material trying out is a vital part of FAI. It guarantees that the substances used inside the product meet satisfactory and overall performance requirements. For instance, even the tiniest material flaws can result in significant problems in aerospace, automotive, and medical gadgets. Testing strategies include checking material composition, energy, durability, and resistance to numerous environmental conditions.

Why Is First Article Inspection So Important?

First Article Inspection is vital because it ensures merchandise meets the best necessities earlier than mass production. It enables the discovery of troubles in layout or production early, saving money and time. FAI builds agree with this as customers feel assured that their product meets strict requirements. Additionally, it guarantees compliance with regulations and certifications in diverse industries. The initial product verification process also reduces waste by catching defects early, preventing the manufacturing defective products. Without FAI, mistakes can be ignored, mainly due to highly-priced recollects or patron dissatisfaction.

Purpose of first article inspection & why choose FAI service

The purpose of quality control in manufacturing is straightforward: to ensure that the production manner and product meet all design and best requirements. FAI improves accuracy by providing a product that matches its design. It enhances pleasant management by verifying that manufacturing methods produce constant consequences. Customers gain from more satisfaction, as FAI report documentation provides peace of mind that merchandise is excessively satisfactory. Moreover, FAI is time- and price-efficient because it identifies problems before mass manufacturing, keeping off pricey mistakes. Manufacturing compliance standards offerings carry understanding, advanced tools, and impartial inspections. This guarantees dependable effects and saves producers time and resources.

How do you ensure FAI quality control in your manufacturing process?

Ensuring FAI high-quality control requires a scientific approach. To start, you need thorough documentation. Gather layout drawings, specifications, and consumer necessities. Create a tick list for inspection to ensure all factors are covered.

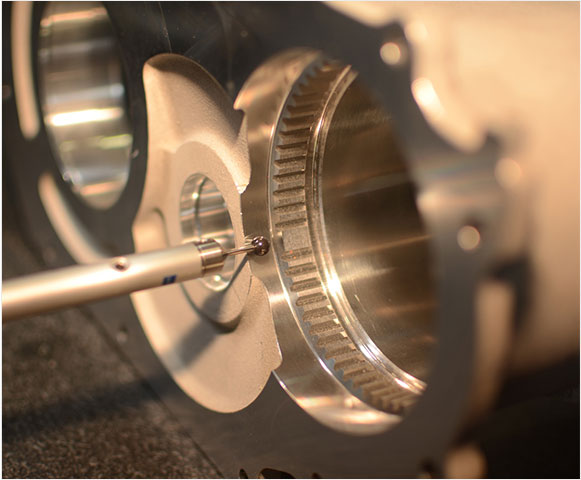

Next, look at the primary article by measuring dimensions, checking cloth properties, and checking product capability. Compare the effects of the layout requirements. Verifying manufacturing tactics is another essential step.

Ensure all equipment is calibrated and that operators follow standard tactics. Recording effects is critical. Document all findings in an FAI file and encompass snap shots, measurements, and test outcomes for destiny reference.

Finally, the file will be assessed and approved. Have skilled inspectors evaluate the report and deal with any troubles before approving mass production. By following those steps, you may keep first-rate requirements and reduce dangers.

How do you find a reputable first article inspection services provider?

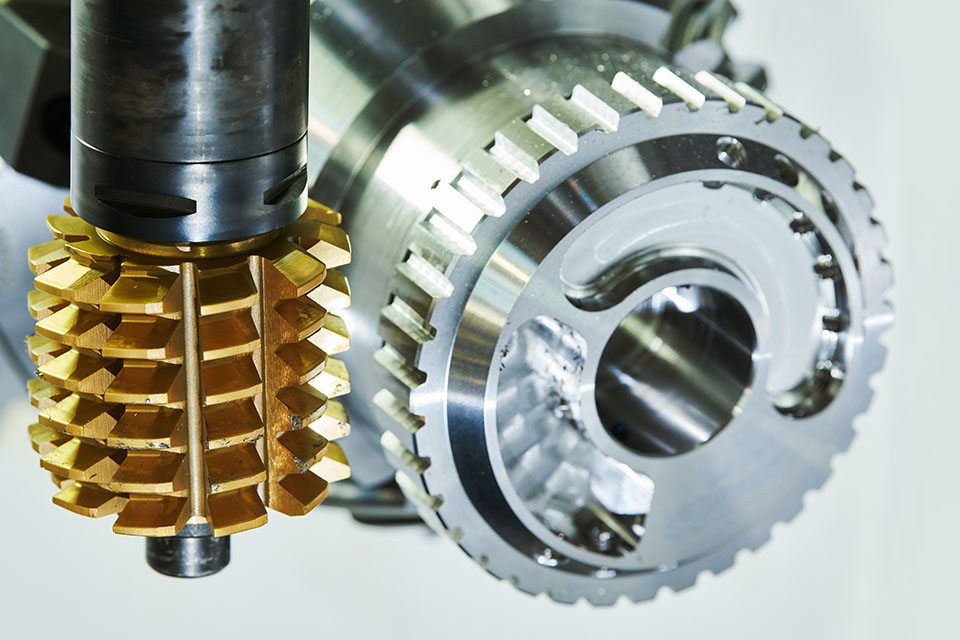

Choosing the proper FAI service provider evaluation is essential for achievement. Start using looking for experience and knowledge. Select an issuer with years of experience in your enterprise who is familiar with your product’s necessities and requirements. Advanced gear is another crucial element. A precise company makes use of contemporary gadgets for accurate checking out.

Ensure the issuer has a qualified group. Inspectors should have proper training and certifications. Comprehensive offerings are also crucial. Look for an issuer that provides end-to-stop material testing and inspection services, documentation, and reporting. Finally, check consumer opinions or ask for references to verify their reliability. By choosing a truthful provider, you can ensure your FAI manner runs smoothly and successfully.

Best First Article Inspection Service Company in China

Regarding FAI offerings in China, Junying is a standout choice. Junying has been enjoyed for a long time in CNC production and dimensional measurement accuracy. They offer one-forestall services, CNC machining components, and CNC machining prototypes. Junying centers today consist of advanced CNC machines, lathes, blasters, and Ultra Sonic washing machines. The corporation also has a professional team of engineers, operators, and inspectors who make certain pinnacle-notch first-class. Junying works carefully with OEM clients to turn their designs into facts. Dedication to pleasant innovation and purchaser pride makes them reliable FAI service associates.

The Finishing Line

First Article Inspection is a crucial step in the production process. It ensures that products meet layout requirements, improves first-rate manipulation, and saves money and time. Producers can streamline tactics and deliver splendid merchandise by operating with an experienced FAI carrier issuer like Junying. Whether you’re beginning a new assignment or improving existing ones, FAI is essential for fulfillment in production.