Hello there! Gear hobbing is a fascinating process. It’s a method to make gears. A special tool called a “hob” is the star here. This hob looks like a worm gear. When gear hobbing, both the hob and the workpiece rotate. As they spin, the hob carves out the gear teeth on the workpiece. It’s a bit like sculpting but for metal. This method is popular because it’s efficient and produces good quality gears. So, the next time you see a gear, just think: maybe hobbing helped create it!

How Gear Hobbing Works?

If you’re wondering what that is, gear hobbing is a process to make gears. It’s like sculpting but for metal pieces. So, how does it work? Let’s see it down step-by-step.

Understand the Basics

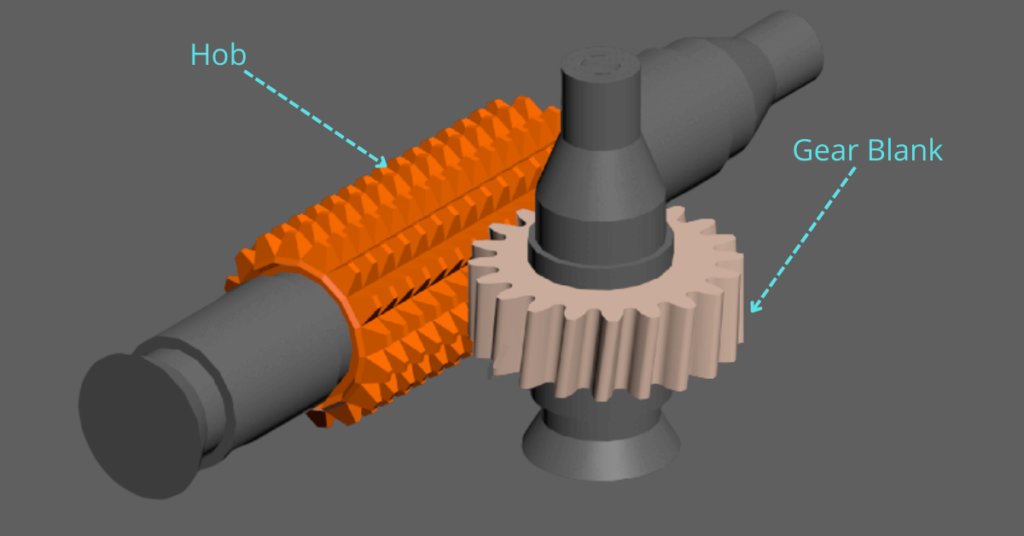

Before we start, know this: gear hobbing uses a special tool. This tool is called a “hob”. It looks like a worm gear. The workpiece, which will become our gear, spins next to this hob.

Choose the Right Hob

Different gears need different hobs. Choose a hob that matches the gear profile you want. This ensures that the teeth come out perfectly.

Set Up the Machine

You’ll use a machine for this process. Make sure it’s clean and free of debris. Place the workpiece (your future gear) onto the machine. It should be in a fixed position. Mount the hob onto the machine too. It should be at an angle. This angle is usually the helix angle of the hob.

Decide on Rotation Speeds

Both the hob and the workpiece will spin. Their speeds should be synchronized. This means they turn in a way that the hob cuts the workpiece evenly. Check your machine’s manual for recommended speeds. They often give the best results.

Start the Machine

With everything in place, turn on the machine. The workpiece and the hob start rotating. The hob begins cutting into the workpiece. It starts carving out gear teeth.

Move the Hob Across the Workpiece

The machine will move the hob across the workpiece. It’s like when you slice bread. The knife (hob) moves through the loaf (workpiece). This motion ensures all teeth get cut evenly.

Monitor the Process

Keep an eye on things! The cutting should be smooth. The machine will usually make a consistent sound. If you hear odd noises, stop and check. Ensure there’s enough cutting fluid too. It keeps things cool and smooth.

Complete the Cut

Let the machine run until the hob moves across the entire workpiece. When it reaches the end, the gear teeth are fully shaped.

Turn Off the Machine

Safety first! Once done, turn off the machine. Wait for all moving parts to stop.

Inspect the Gear

Take out the workpiece. Now, it’s transformed into a gear! Check the teeth. They should be sharp and even. If they look good, congratulations! You’ve successfully made a gear.

Clean Up

Cleaning is essential. Remove metal shavings from the machine. Clean the hob and work area. This ensures your workspace is ready for the next project.

There you have it! That’s how gear hobbing works. While the process might seem complex, breaking it down makes it manageable. With practice, you can create the perfect gear every time. Remember, always follow safety guidelines. Machines are powerful and can be dangerous. But with attention and care, they’re fantastic tools.

What is the difference between gear hobbing and gear cutting?

Making them involves a few methods. Two popular ones are gear hobbing and gear cutting. Let’s see the differences between them.

1. Method of Operation

Gear hobbing uses a special tool called a “hob”. The hob and the workpiece both rotate. As they turn, the hob carves out gear teeth. It’s like a dance between the two!

Gear cutting, on the other hand, uses a different approach. It employs a cutter shaped like the space between gear teeth. This cutter slices into the gear blank. Think of it as a cookie-cutter for gears!

2. Type of Gears Produced

Gear hobbing mostly makes helical and spur gears. These are common gear types you’ll find in many machines.

Gear cutting offers more variety. You can produce spur gears, helical gears, bevel gears, and more. It’s a bit more versatile.

3. Speed and Efficiency

Hobbing is usually faster. Once you set it up, it carves out teeth swiftly. It’s great for producing lots of gear in a short time.

Gear cutting is more deliberate. Each cut takes time, especially for intricate gears. But, it gives high precision and quality.

4. Finish and Accuracy

Both methods provide accurate gears. But, gear cutting often offers a smoother finish. This is because it takes its time with each cut.

Hobbing is speedy. Sometimes, this means the finish might need some extra polishing.

5. Flexibility

Gear cutting is versatile. It can handle various gear profiles and sizes. It’s like the Swiss Army knife of gear-making.

Hobbing specializes in what it does. While it’s fantastic for spur and helical gears, it has its limits.

Final Thoughts

Both gear hobbing and gear cutting have their merits. Choosing between them depends on your needs. If you want speed, hobbing is your friend. For versatility and finish, cutting might be the way to go. Either way, both methods craft the gears that keep our world turning.