Enjoy the exciting world of electropolishing solutions! Ever think about how metal gets its smooth, shiny looks? It focuses on specific cures applied to electropolishing. The sulfuric acid serves to give stainless steel a glossy look. Aluminum brings its shine from phosphoric acid. Perchloric acid is a way to give titanium a special touch. Yet, citric acid for stainless steel is an option if you’d like things to be better. It’s not all about the acids. There are also unique mixes, such as a metal-magical potion. These pairings add some extra shine and polish to your metalwork. This guide is for all, whether a beginner or an expert. It is the best site for studying electropolishing solutions. Get set to see your metalwork shine, keep its size, and have a superb look.

What solution is used for electropolishing?

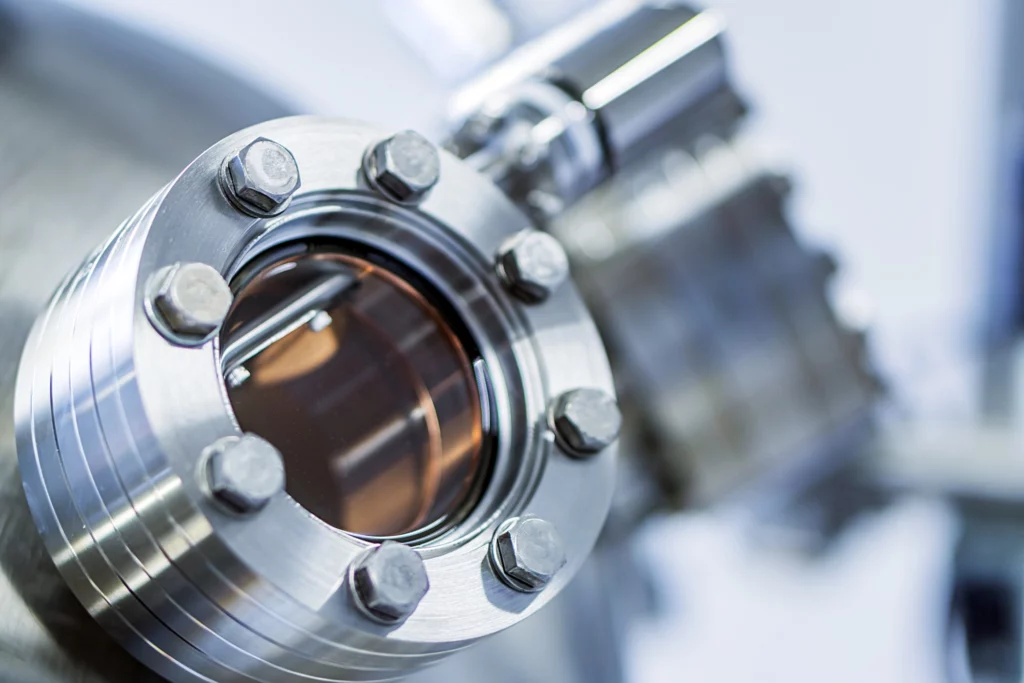

Electropolishing feels like giving metal surfaces a stunning change! The metal has a smooth, glossy look because of its unique method. An electrical reaction removes a small layer. Think about how it feels like a spa day for your favorite metal item!

- Now, let’s explore a specific solution used in this method. It is known as the “electrolyte solution.” There are various types of solutions for multiple metals. A choice often made is a sulfuric acid (H2SO4) solution. Stainless steel and other metals seem stunning with this extra barrier.

- For aluminum and other supplies, there is one more choice. It is also the solution of phosphoric acid (H3PO4). It does a great job keeping these metals’ flawless, smooth look. For aluminum surfaces, it’s equal to a hero!

- We use a perchloric acid (HClO4) solution while using metals such as titanium. As it’s a unique mix made just for titanium, it will get special care.

- The citric acid solution is a choice for people who want smoother things. Like a friendly helper, it gives the metal a nice sparkle without being too harsh.

It’s like a chemical party, with various acids and other cool things. The unique mixture offers a united and smooth electropolishing action. A group of stylists is giving the metal a makeover!

But be careful—using these solutions is similar to working with potions. As with a science lab, you must be very careful and follow safety rules. Safety first, at all costs!

Hold these points in mind when you give your metal item a spa day or are trying to make it look nice. Electropolishing is also ideal for creating a fantastic look on metal things!

What are the advantages of electropolishing?

Think of electropolishing as a solid shield for metal items. It offers much more for them than just making them look great. They become strong, too! Electropolishing is a method that gives metal items a shiny, smooth surface. But looks are not all. It is like creating an invisible layer that protects them from corrosion. It removes any minor lumps or sharp edges, making them much safer to handle. See it as removing unseen bars! Things made of electropolished metal get rewards for cleanliness. Anything sticks to them, much like Teflon-coated pans! It is practical, particularly in hospitals and kitchens, where purity is vital. Also, all these fantastic changes occur without the metal being reduced or expanded. It’s like tricks, only more helpful. If you see anything smooth and shiny, it may have received electropolishing. Also, it keeps it strong, secure, and spotless, and the sides offer it an ideal look!

Where can I learn more about electropolishing?

Are you curious about the method of electropolishing metal to make it smooth and shiny? You can visit a great webpage. Julying Metal Manufacturing Co., Ltd. is the name of the company. Many clear articles and facts explaining the process of electropolishing are out there. Also covered is an explanation of how it applies to various metal items. A superb source for more data is Junying’s website. They are ready to assist you, whether you’re getting started or have some expertise. You will learn a lot and learn exciting facts by visiting their site.

FAQs

What is electropolishing?

Electropolishing makes metals smooth and shiny using electricity and special liquids.

Is the electropolishing liquid dangerous?

Yes, it’s solid and can hurt you if handled carefully. Always wear safety gear.

What makes the liquid work better or worse?

How much acid is in it, the temperature, and how long you use it can change how well it works.

Are there any environmental worries with these liquids?

They must be thrown away carefully so as not to harm the environment. Follow the rules when disposing of them.

How do you make the electropolishing liquid?

Mixing the acids and other parts is essential. It must be done safely and precisely.

Can the liquid be made to do unique things?

You can change the mix to get different types of shines or textures. An expert can help you make the perfect mix for what you need.

Conclusion

A vital part of this process is the particular liquid that smooths and glows metals. Typically, this liquid is a blend of solid acids chosen from various metals. It is reliable, so beware while handling and removing it. To protect our planet, we must follow this rule. Picking and applying the right liquid to the metal will help create the best, shiny, smooth wrap-up.