CNC turning is a popular method in modern-day production. It is unique, green, and reliable for making outstanding parts. We explore CNC turning, how it works, its packages, and its advantages. We’ll also look at the forms of machines used and why CNC production offerings in China, like the ones provided with the help of Junying, are most of the best.

What Is CNC Turning?

CNC turning is a manufacturing technique that shapes materials into cylindrical elements. CNC stands for Computer Numerical Control, and a computer publications the procedure. Turning refers to the rotation of the workpiece, whilst a cutting device eliminates material to create the desired shape. This procedure is frequently used to make gadgets like shafts, bushings, or screws.

The use of CNC machines guarantees excessive accuracy and repeatability. This way, each piece seems and works the same. It is ideal for industries where precision is vital.

How Does CNC Turning Work?

CNC turning begins with a raw material, typically within the shape of a rod or bar. The material is secured in a device known as a lathe. Once secured, the lathe spins the fabric at high speeds.

A reducing tool, controlled using the CNC device, moves alongside the fabric to remove layers. The tool follows a programmed direction, ensuring the exact dimensions of the last product. Operators also can use a couple of equipment for complex shapes and features. The CNC program tells the system to replace equipment, alter speeds, or make cuts.

Because the process is automated, precision machining techniques reduces mistakes and quickens manufacturing. It can also take care of both easy and intricate designs.

What Part Shapes Need CNC Turning?

CNC turning is nice for developing cylindrical or round shapes. Common examples include pipes, rings, and axles. It is likewise used for elements with threads, grooves, or holes. The method can create both straightforward and complex designs with smooth finishes.

Different CNC tactics like milling can be desirable for parts that can be flat or non-cylindrical in general. However, turning may be combined with milling for hybrid designs.

Advantages of CNC Turning

CNC turning gives many blessings over guide machining and different production methods. It affords high precision. The computer-guided system guarantees every component meets specific specifications.

It is fast and green. Once programmed, the system can produce massive quantities quickly. This makes it value-powerful for mass manufacturing.

CNC lathe operations improves protection. Operators don’t need to handle gear without delay during the technique. This reduces the hazard of injuries.

It is flexible. Metal fabrication with CNC works with many substances, including metals, plastics, and composites. It also allows for customization and versatility in design.

The method minimizes waste. The unique cutting reduces material waste, making it an eco-friendly alternative.

CNC Turning Applications Across Industries

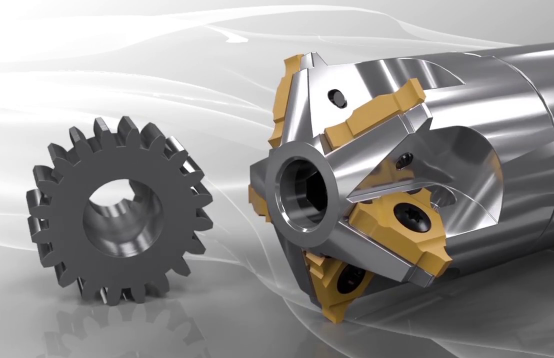

CNC turning applications is utilized in numerous industries due to its precision and flexibility. It produces engine components, gears, and axles in the car area. Aerospace corporations depend upon CNC turning for parts like generators and touchdown equipment.

The scientific discipline uses it for surgical equipment and implants, even as the electronics industry creates connectors and housings. Even inside the patron items market, cylindrical part production plays a role in making gadgets like pens and watches. Its potential to supply long-lasting and specific components makes it valuable in almost every industry.

Key CNC Turning Process

Advanced manufacturing processes manner involves numerous steps. It begins with designing the part using CAD (Computer-Aided Design) software. The CAD version is then converted into CNC software that courses the gadget.

Next, the raw material is loaded into the lathe. The CNC machine starts offevolved cutting in step with this system. Operators reveal the process to ensure the whole thing runs efficiently.

After slicing, the component may fit through finishing approaches like sprucing or coating. Finally, the finished element is inspected for satisfaction and accuracy before shipping.

Types of CNC Turning Machines

There are specific styles of CNC turning machines, and everyone applies to particular duties. Horizontal lathes are the most common. They are versatile and paint nicely in many styles and sizes.

Vertical lathes are used for large, heavier parts. These machines keep the fabric vertically, making it less challenging to work with cumbersome items.

Swiss lathes are another kind designed for high-precision paintings. They are regularly used in the medical and electronics industries.

Multi-axis lathes add greater flexibility. They can flow the cutting tool in a couple of instructions, taking into account extra complicated designs. These machines are best for advanced initiatives requiring specific features.

The Best Place for CNC Manufacturing Services in China

Junying sticks out for reliable and super CNC manufacturing offerings in China. With a long history, Junying has provided one-stop offerings for CNC machining elements and prototypes. They cater to OEM customers and handle everything from layout to final transport.

Junying’s facilities encompass superior computer-guided machining systems, lathes, and different equipment. They even use specialized systems like blasters and ultrasonic washing machines. This ensures each part meets the highest standards.

The business enterprise’s professional crew includes experienced engineers, operators, and inspectors. They work together to show customer designs into fact. Junying is known for its precision, reliability, and consumer-focused method. Whether you need small batches or mass manufacturing, Junying can deliver.