Electrical discharge machining (EDM) is a unique method of making elements with fantastic precision. It uses tiny electric sparks to cast off cloth from a bit, shaping it into the preferred form. This approach is beneficial at the same time as jogging with harsh substances, which makes it challenging to reduce the usage of ordinary equipment. EDM machining process is used in many industries, including aerospace, vehicle, and tool making.

We can explain how sinker EDM works, the substances it can be used on, and who offers excellent EDM products.

What is Electrical Discharge Machining?

Electrical Discharge Machining (EDM) is a way in which electric sparks are used to form a cloth. These sparks are so warm that they soften or vaporize small quantities of the fabric. The cloth is then removed using the pressure of the sparks and the cooling liquid, which prevents the fabric from overheating.

This method may be exact because the tool (an electrode) doesn’t contact the fabric right now. The electric sparks create an opening between the electrode and the cloth, and the sparks paint tiny portions of the fabric away in a controlled way. Wire EDM cutting is excellent for reducing challenging shapes and information into harsh substances like steel, making it perfect for industries where excessive precision is needed.

Sinker EDM and wire EDM are the most essential types of EDM. Both strategies use the same principle of electrical sparks but use unique methods to utilize those sparks in the cloth.

Working Principle of Electrical Discharge Machining

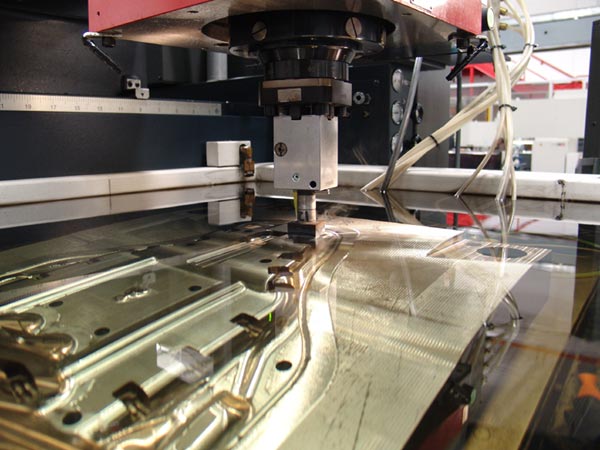

The working principle of CNC EDM machines is simple but powerful. The approach begins with a strength delivery that sends an electric current to the electrode. The electrode gets very near the fabric but doesn’t contact it. The region between the electrode and the cloth contains a special liquid called dielectric fluid.

The dielectric fluid changes into a conductive course when the electrical cutting edge is applied. This creates a spark between the electrode and the material. The spark is extremely warm and melts or vaporizes small bits of the material. The melted fabric is then carried away by the dielectric fluid, leaving in the back of a smooth, fashioned ground.

This manner may be repeated often to carve out minimal, particular information. Because the electrode doesn’t physically contact the fabric, there is no chance of adverse it with mechanical stress. EDM is best for making small, specific components, which incorporate those wanted in molds, equipment, and even sensitive machine additives.

Types of Electrical Discharge Machining Materials

EDM may be used on many excellent types of substances. Still, it works specifically properly with complex, harsh substances that can be hard to use with traditional equipment. Some of the most commonplace materials that EDM is used for include:

Tool Steels: Tool steels are harsh and used to make gear and dies. EDM permits the creation of particular shapes in these materials, so it’s frequently used in device making.

Titanium: Titanium is a lightweight and sturdy material used in aircraft and medical gadgets. EDM can shape titanium parts with high precision, making it a notable choice for these industries.

High-speed steel (HSS): This high-speed metal is used in gadgets that must remain sharp and strong, even at high temperatures. EDM is used to reduce complicated shapes from HSS.

Superalloys: Superalloys are materials designed for painting in excessive temperatures. They are difficult to devise, but EDM can address them, making them the best choice for the aerospace and strength era.

Copper Alloys: Copper is an excellent conductor of energy and warmth, so it’s often used to make electrodes for EDM machines and as workpieces in EDM.

Carbon Steels: Carbon steel is one of the most used substances in creation and agency. EDM can create designated shapes in carbon steel, which is essential for making factors with complex designs.

Ceramics: Ceramics are hard, brittle materials in electronics and clinical gadgets. EDM can reduce those substances without breaking them.

Graphite: Graphite is usually used for electrodes in EDM because it wears down slowly and conducts energy properly.

The Top Electrical Discharge Machining Service Provider

Junying Metal Manufacturing Co. is one of the best high-quality EDM machining services providers. With over a decade of experience in CNC manufacturing and EDM services, Junying is an expert in precision machining for many industries, including aerospace, vehicles, and clinical.

Junying offers a one-stop service for OEM clients, meaning it can handle everything from the format segment to the final production of components. The company uses hundreds of advanced and High-precision machining and EDM systems, ensuring splendid outcomes. Its skilled engineers and operators ensure the work is completed correctly every time.

Junying’s dedication to quality and precision has made It a trusted companion for many businesses that need Dielectric fluid in EDM. Whether you need a prototype or a complete production run, Junying can supply reliable and precise results.